3D Printing Services

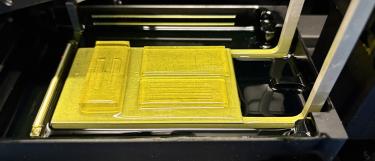

With our high precision 3D printer (microArch S140, Boston Microfabrication) we are able to fabricate microfluidics chips with channels down to 50µm in diameter. Even thought photo lithography has many advantages for the fabrication of microfluidic devices, by using a 3D printer we are generating new possibilities. The most prominent example is a microfluidic device we fabricated with channel openings on the side with a round diameter of 750µm, thinning to only 100µm in the middle of the device. Further, the center contains a chamber which is open on the top and connected to the 100µm channels on either side. Such devices are not possible to fabricate with lithography processes, molding techniques or layer-by-layer assembly methods. The image on the right shows this device.

More information about the printer can be found on the following page:

Soft lithography

Since photolithography is limited to a maximum height of 200µm and flat channels, we increased our portfolio by printing PDMS molds. Here, the advantage is that we can print channels with a wide variety of different channel geometries, such as tilted roofs. Additionally, PDMS can be molded from structures in the mm range, which opens up the possibilities for the culture multicellular objects, such as tissues and organoids.

Printing on Glass

Another advantage of our printer is the option of printing on glas. This is useful for applications which do not allow to mold PDMS from the structures and plasma bond them to a glas surface. An example for this is the fabrication of small, embedded channels inside the print, with the need of open structures, such an example can be seen in the image on the right. Here, single chambers are connected to narrow channels (100µm in diameter) and are enclosed by the glas slide on the bottom and open on top.

Hollow channels

Finally, we can print entire structures with narrow, hollow channels embedded in a printed structure, with the smallest resolution of around 50µm. Those devices are widely used for mixing of liquids or generating gradients, without the need of observing the events.